Metal Inserts for Attachment

Single Crystal Si is not like ductile materials that allow threading and direct mechanical attachment to other materials, however with our frit bonding method, we can attach Single Crystal Si into metal hardware through the use of metal inserts.

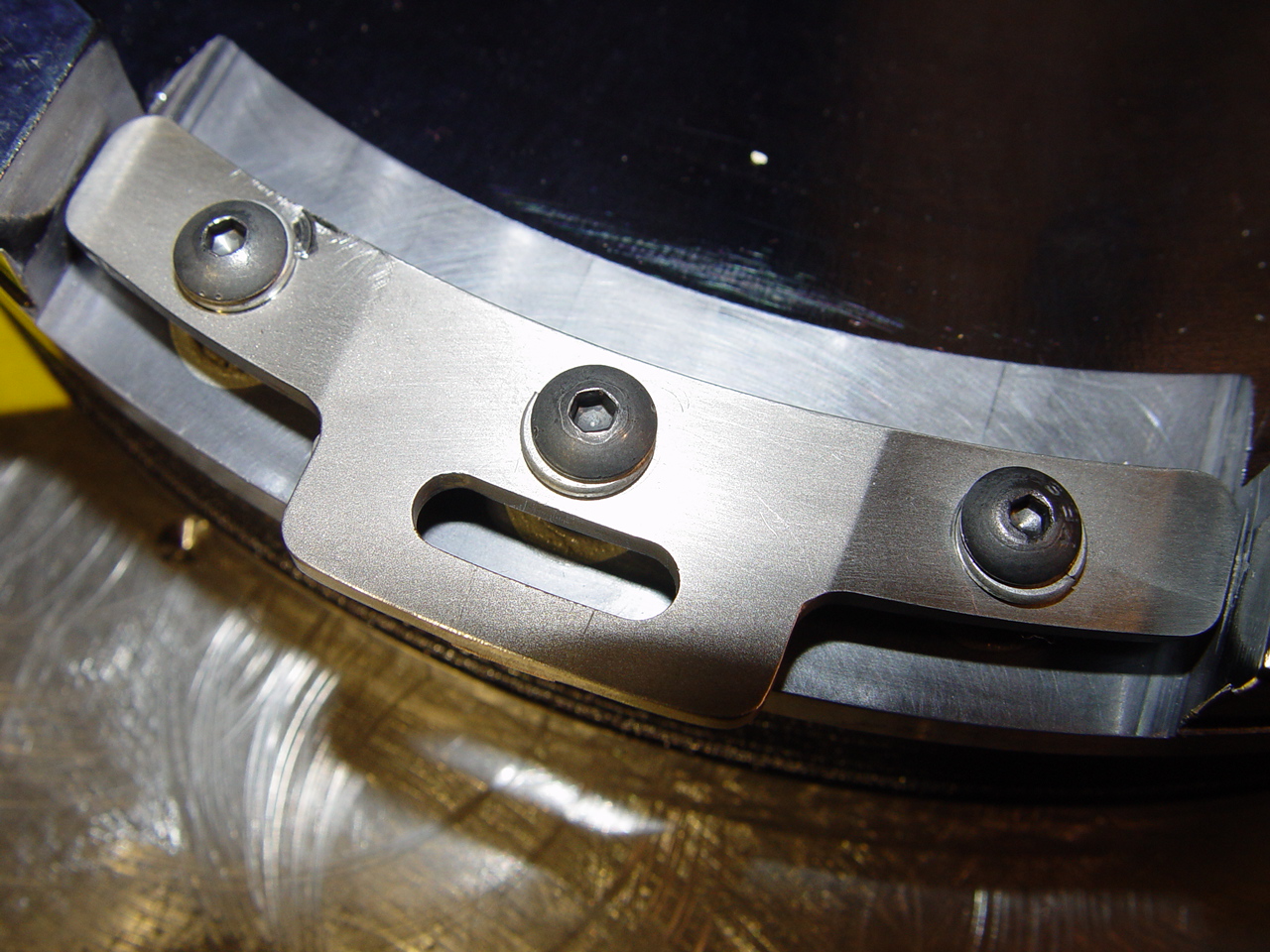

Close up of side inserts

Through the years, we have developed several attachment concepts using 39NiFE, a crysostable material, for the inserts, to serve as an interface between the Single Crystal Si optic structure and the metal hardware of the vehicle. Bonding the NiFe to Single Crystal Si involves designing the joint so that it allows for the thermal mismatch between the silicon and the NiFe, which then causes the joint to act as a metallurgical joint versus a mechanical one. Then, the stress in the joint is distributed throughout the bond layer to a degree that is considered low and stable. Additionally, the frit attaches and fuses with the two materials without the creation of a eutectic or erosion of the Single Crystal Si surface leading to a higher and longer term stability.

Integrated Scraper Concept

While our rigid inserts tested successfully using NASA flight requirements, for extreme and harsh environments, rigid inserts most likely would not serve adequately because the systems do not allow for movement, which adds residual stress. Our built-in flexure design can address the issue of residual stress in a brittle material by allowing radial and torsional movement.

Our frit-bonded metal inserts allow for direct attachment, eliminating mounting cans, fixtures, and other hardware along with the cost, weight, and mass attributed to them.

The inserts create a modular concept for production and auto-alignment functions, which together, reduce the cost and time for assembly.

Secondary Mirror with Compact Modularity - Mount Side

Secondary Mirror with Compact Modularity - Mirror side up